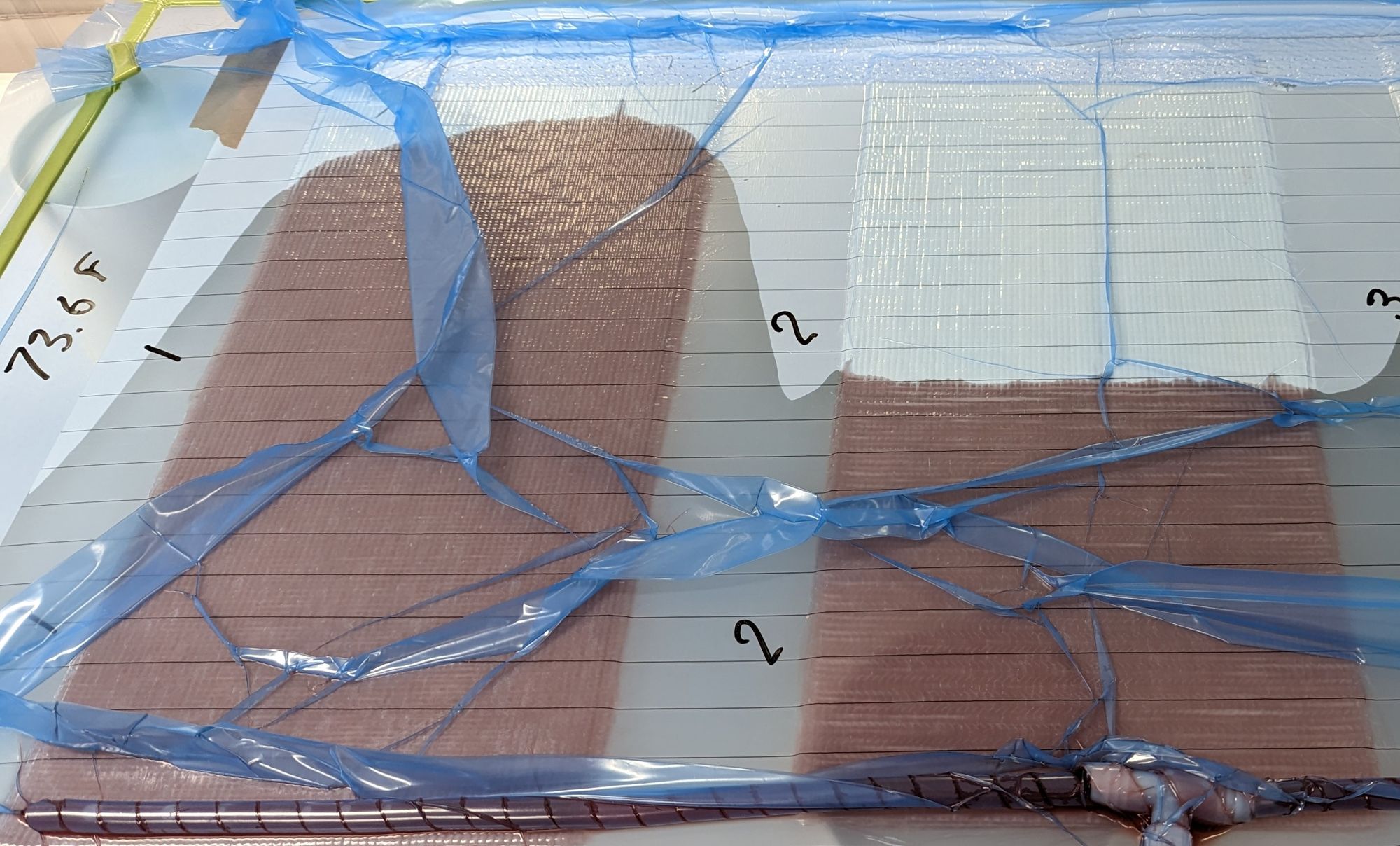

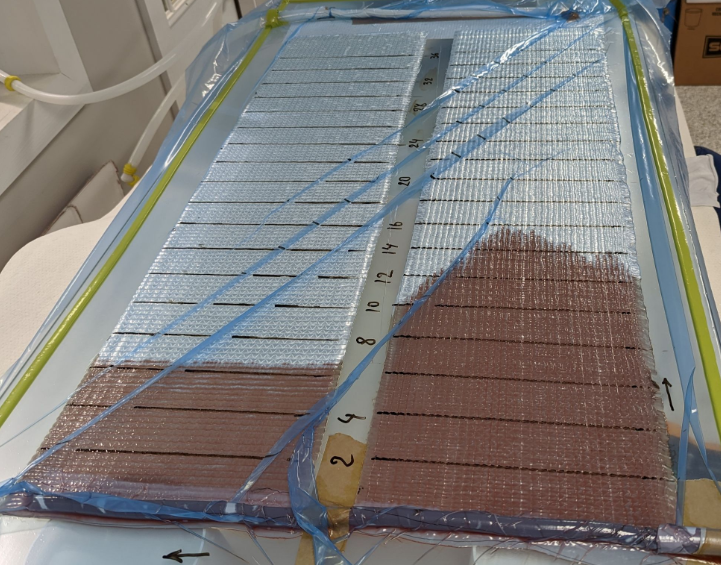

Fabric permeability testing is an essential step conducted prior to the resin vacuum infusion process. This testing allows for the calculation of infusion time and simulate the part infusion process.

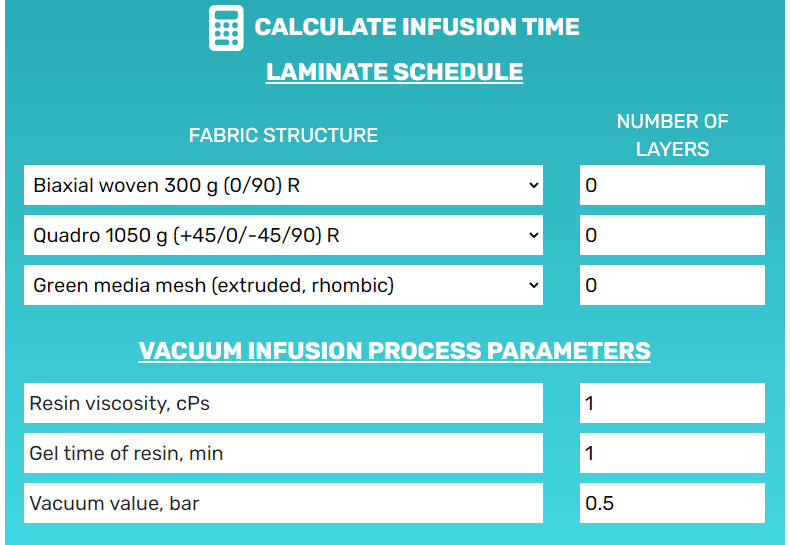

To simplify the selection of an infusion process, a calculator can be utilized to determine the infusion time (https://infusionboat.com/#calculator). This calculator is based on a simplified one-dimensional model of Darcy's law (which describes the flow of liquids through a porous medium).

It is crucial to acknowledge that the permeability coefficient depends on various parameters, including fiber type, lubricant type, fabric structure, resin type, and process conditions. Fabrics are complex materials, not just fibers. Remember also that the fabric may have different warp and weft permeability. This is essential for a successful infusion process.

Therefore, it is highly recommended to test the materials and laminates under the intended process conditions before designing an infusion process. This testing will provide valuable insights into the behavior of the materials used.

As an illustration, fabrics with the same structure, such as 0/90+CSM (600g / 600g + 300g), may appear identical with similar markings. However, they possess different permeability coefficients, leading to varying infusion times.

Furthermore, considering that fabric manufacturers often provide minimal information about their fabrics and may not notify you of any changes, it is advisable to test each new batch of fabric. Implementing incoming material control is a crucial factor in maintaining production stability and ensuring high product quality.