In the competitive world of high-performance manufacturing, efficiency and cost savings are paramount. One area ripe for optimization is the resin vacuum infusion process. By fine-tuning this method, companies can significantly reduce consumable usage, save money, and achieve rapid returns on their investment.

The Benefits of Optimization

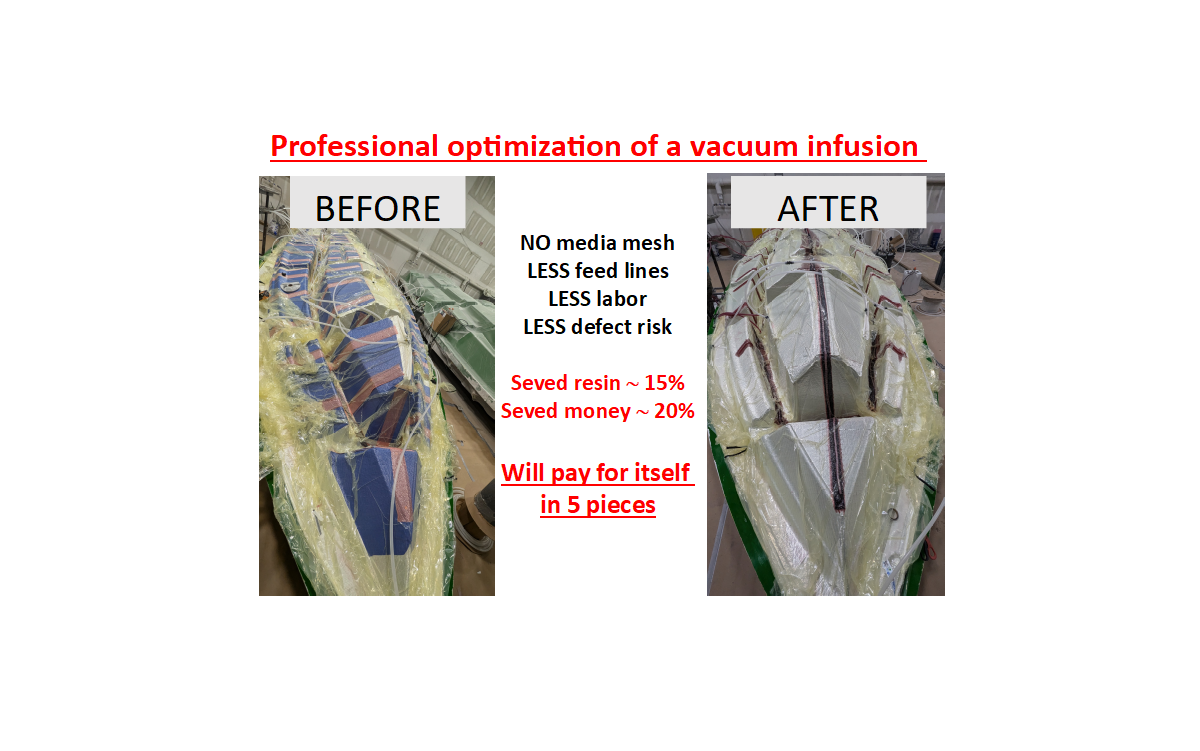

- Reduced Consumables: Optimization of the resin vacuum infusion process leads to more precise resin usage, minimizing waste. This not only cuts down on material costs but also contributes to a more sustainable manufacturing practice.

- Cost Savings: By using less resin and other consumables, companies can see immediate financial benefits. The reduction in waste translates directly to lower expenditure on raw materials.

- Improved Quality and Consistency: A streamlined infusion process ensures better resin distribution, resulting in higher quality and more consistent products. This reduces the likelihood of defects and rework, further saving costs.

- Faster Production Cycles: Enhanced control and efficiency in the infusion process can lead to quicker production times, allowing companies to meet demand more effectively and improve overall throughput.

The ROI of Process Optimization

Investing in the optimization of your resin vacuum infusion process isn't just about saving on materials—it's about boosting your bottom line. High-performance companies can often see their investment returned after producing just five pieces post-optimization. This rapid return on investment (ROI) highlights the significant impact that a well-optimized process can have on a company's financial health.

Steps to Achieve Optimization

- Evaluate Current Processes: We conduct a thorough assessment of your current resin vacuum infusion techniques to identify areas for improvement and determine key optimization points.

- Implement Advanced Technologies: We offer and install advanced sensors, automation, and software to monitor and control the infusion process more precisely.

- Training and Consulting: We train your team in the latest techniques and technologies to ensure they can maximize the benefits of the optimized processes.

- Continuous Improvement: We provide regular consultations and support for ongoing refinement of your processes, helping you maintain optimal efficiency and stay ahead of industry standards.

Conclusion

For high-performance companies, optimizing the resin vacuum infusion process is a strategic move that pays off quickly. By reducing consumables, cutting costs, and improving production quality, businesses can achieve significant financial savings and a swift return on their investment. Utilize our optimization services and watch your company thrive in the competitive manufacturing landscape.

Implementing these changes not only enhances efficiency but also positions your company as a leader in innovation and sustainability. Start optimizing your resin vacuum infusion process with our help today and reap the rewards of a smarter, more cost-effective production method.