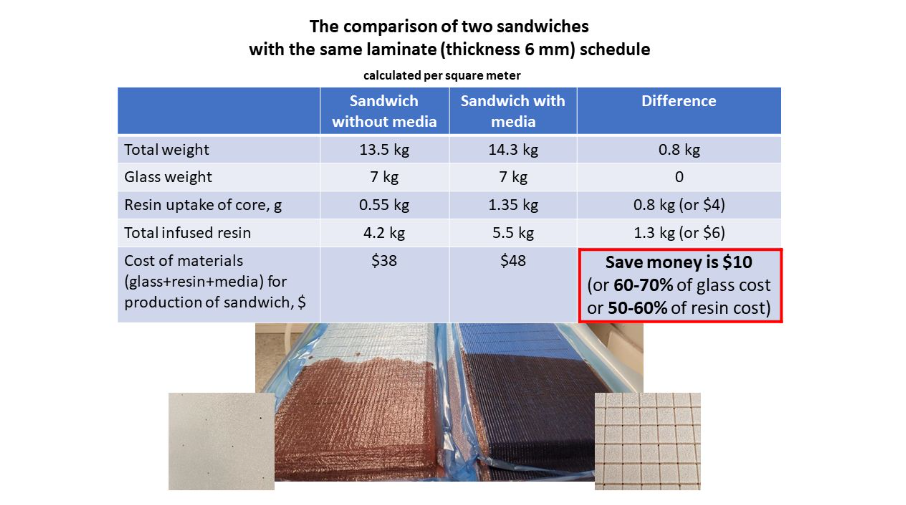

Choosing the correct laminate schedule and vacuum infusion process can indeed result in significant cost savings. In this case, the comparison was made between two sandwiches made with holed foam, one without grooves and media mesh and the other with grooves and media mesh.

Interestingly, both sandwiches were infused for the same amount of time and had almost identical mechanical properties. Obviously, the sandwich without grooves and media mesh was lighter. However, the difference in weight is not the only factor to consider. The use of media mesh resulted in a significant cost savings of $10 per square meter. This may seem like a small amount, but when considering that this value accounts for 60-70% of the glass or 50-60% of the resin cost, it is clear that the savings can be significant. Other cost factors to consider include the cost of foam, media mesh, labor, and other materials involved in the infusion process.

Therefore, it is important to consider all aspects of the vacuum infusion process, including the specific application, to make an informed decision. In some cases, using media mesh may be necessary to achieve the desired infusion time, but in other cases, it may not be needed and can result in unnecessary additional costs.

By carefully analyzing the different factors involved in the vacuum infusion process, such as material costs, labor costs, and the specific application requirements, it is possible to determine the best laminate schedule and vacuum infusion process to optimize cost-effectiveness while achieving the desired mechanical properties.